Every manufacturing executive has heard the pitch: smart factories, digital twins, AI-powered predictive maintenance, IoT sensors everywhere, lights-out manufacturing.

The promise is compelling. The technology exists. The business case is often clear.

Yet most “factory of the future” initiatives stall—not because the technology doesn’t work, but because organizations aren’t ready to use it.

After working with manufacturers pursuing digital transformation, we see the same pattern: companies invest millions in smart manufacturing technology, achieve measurable results in pilot programs—and then struggle to scale beyond a single production line.

The barrier isn’t technical capability. It’s organizational readiness.

The Problem Nobody Wants to Admit

Smart manufacturing fails for non-technical reasons:

- IT and Operations don’t speak the same language or share priorities

- Plant managers resist solutions designed by people who’ve never run a shift

- Maintenance teams don’t trust AI recommendations from models they don’t understand

- Data governance doesn’t exist—nobody owns the truth

- Incentive structures reward yesterday’s metrics, not tomorrow’s capabilities

- Leadership announces transformation but doesn’t fund organizational change

These aren’t technology problems. They’re leadership, culture, and operating model problems.

And no amount of advanced technology fixes them.

Why Technology-First Approaches Fail

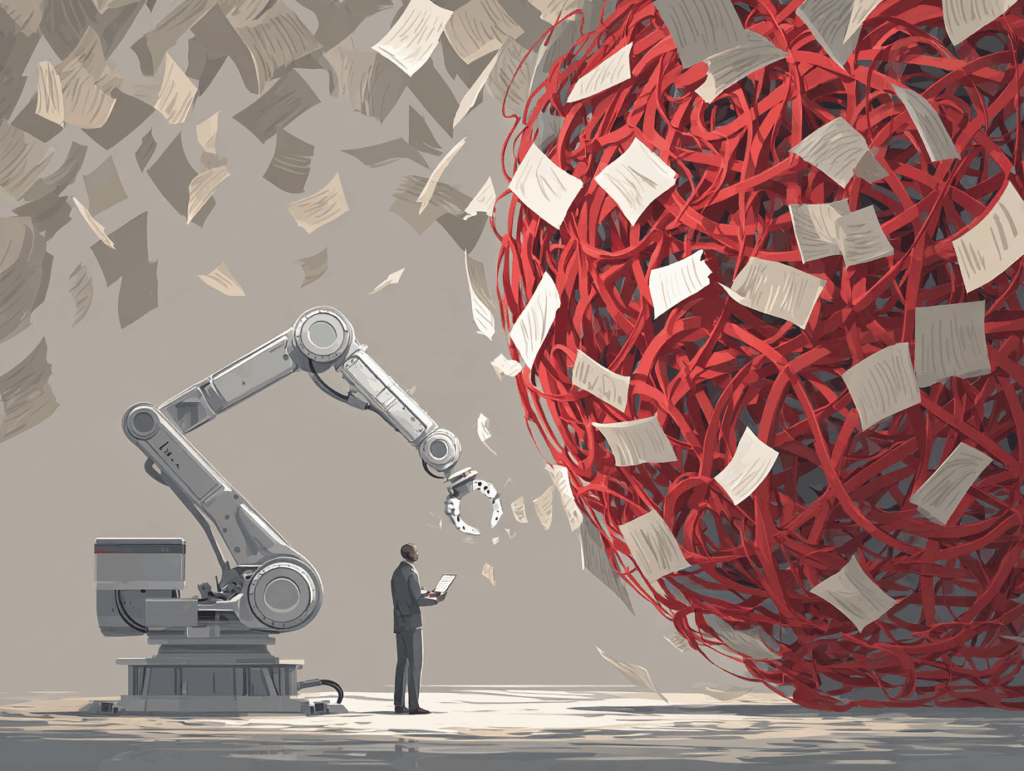

Most digital factory initiatives start backwards: “We need IoT sensors. Let’s install them. Let’s build a data lake. Let’s implement AI models.”

What’s missing: Who will use these insights? What decisions will change? What organizational capabilities must exist to act on recommendations? How will roles and workflows evolve?

Technology deployed into broken processes just automates dysfunction. Smart sensors generating insights nobody acts on don’t improve operations—they create expensive dashboards.

The Rule: Don’t digitize chaos. Fix the organization first, then add intelligence.

The Four Organizational Barriers

1. The IT-Operations Divide

IT teams design for scalability and security. Operations needs tools that work on the factory floor—right now, in harsh conditions, with minimal downtime.

When these groups don’t collaborate, you get technology that’s impressive but operationally impractical, data architectures that don’t match how plants work, and solutions optimized for corporate IT standards instead of manufacturing reality.

We’ve seen manufacturers spend millions on IoT platforms that plant managers refuse to use because the systems don’t fit their workflows.

The Fix: Start with the operational problem and work backward to technology. Co-design solutions with the people who’ll actually use them.

2. The Trust Gap

Plant managers have decades of experience. They know their equipment intimately—the sounds before failure, the quirks of each machine, the workarounds that keep production running.

Then corporate announces an AI system will predict failures better than they can. The predictable reaction: skepticism and resistance.

When one manufacturing client implemented predictive maintenance, plant managers initially ignored AI recommendations because they didn’t understand how models worked. Equipment failures that could have been prevented still happened—not because the AI was wrong, but because nobody acted on it.

The Fix: Build trust before deploying AI. Show plant teams how models work, involve them in validation, and prove the technology makes their jobs easier—not obsolete.

3. The Skills Gap

Smart factories require different capabilities: data literacy, systems thinking, digital tool proficiency, and the ability to work with AI-powered systems.

Most manufacturing workforces weren’t hired or trained for this. The gap shows up as operators who can’t interpret dashboards, maintenance technicians struggling with sensor diagnostics, and supervisors reverting to manual tracking because they don’t trust digital systems.

Studies show that a significant percentage of manufacturing workforces lack basic data analytics experience—yet companies invest heavily in smart manufacturing technology without equivalent investment in training the people who need to use it.

The Fix: Workforce development isn’t optional—it’s foundational. Budget for training, create learning paths, and celebrate digital fluency as a core competency.

4. The Incentive Misalignment

Organizations reward what they measure. If smart manufacturing success isn’t reflected in how people are evaluated and compensated, adoption will fail.

Common misalignments: plant managers measured on uptime resist predictive maintenance requiring planned downtime, maintenance teams compensated for reactive repairs resist prevention strategies, and executives demand transformation but don’t fund change management.

The Fix: Audit your incentive structures. If they reward old behaviors, digital transformation is doomed regardless of technology quality.

What Works Instead: Organization-First Transformation

Smart manufacturing succeeds when companies flip the sequence.

Instead of: Technology → Implementation → Hope People Adapt

Do this: Strategy → Organization → Technology

Step 1: Define the Business Outcome

Start with the specific business problem costing real money: calculate your unplanned downtime costs, quantify quality defects creating rework, assess maintenance cost trends, or measure inventory waste from poor forecasting.

Quantify the financial impact and define success in measurable business terms—not technical metrics.

Step 2: Design the Operating Model

Before selecting technology, answer organizational questions: Who owns digital transformation? How will jobs evolve? Which workflows must change? How do we build trust in data-driven decisions? How do we bring skeptical plant managers along?

One global industrial company we worked with started their predictive maintenance strategy with organizational readiness assessment—data governance, workforce capabilities, IT-operations alignment, and change management needs. Only after addressing these did we design technical architecture. The result: a strategy ready for implementation, not just another pilot that would stall.

Step 3: Select & Deploy Technology

Only now do you choose platforms and vendors. With strategy clear and organization ready, technology decisions become obvious. You know what problem you’re solving, what capabilities must exist, and what workflows the technology must support.

Technology becomes the enabler of organizational transformation—not a replacement for it.

The Factory of the Future Requires the Organization of the Future

Digital transformation fails when companies treat it as a technology project. It succeeds when leaders recognize it as organizational transformation that happens to use technology.

The factory of the future needs leadership alignment, IT-operations collaboration, trust-based adoption of data-driven decisions, workforce capability development, aligned incentive structures, and change management discipline.

Get the organization right, and technology becomes powerful. Get it wrong, and technology becomes expensive decoration.

Ready to Build Smart Manufacturing That Actually Works?

At 212 Growth Advisors, we help manufacturing leadership teams design digital transformation strategies that address organizational readiness, not just technical capability. We build AI strategies grounded in operational reality, design governance frameworks that enable speed, and create change management approaches that build adoption rather than resistance.

If your smart manufacturing initiative is stalling—or if you want to avoid that outcome—let’s talk about getting the organization ready before deploying the technology.